From engineer to entrepreneur: UM alumnus Ken Cheong charts a path for success

從工程師到傑出企業家 澳大校友張嘉和繪出成功軌跡

UM develops novel magnetic soft robots with on-demand hardening

澳大成功研發新型磁控機器人

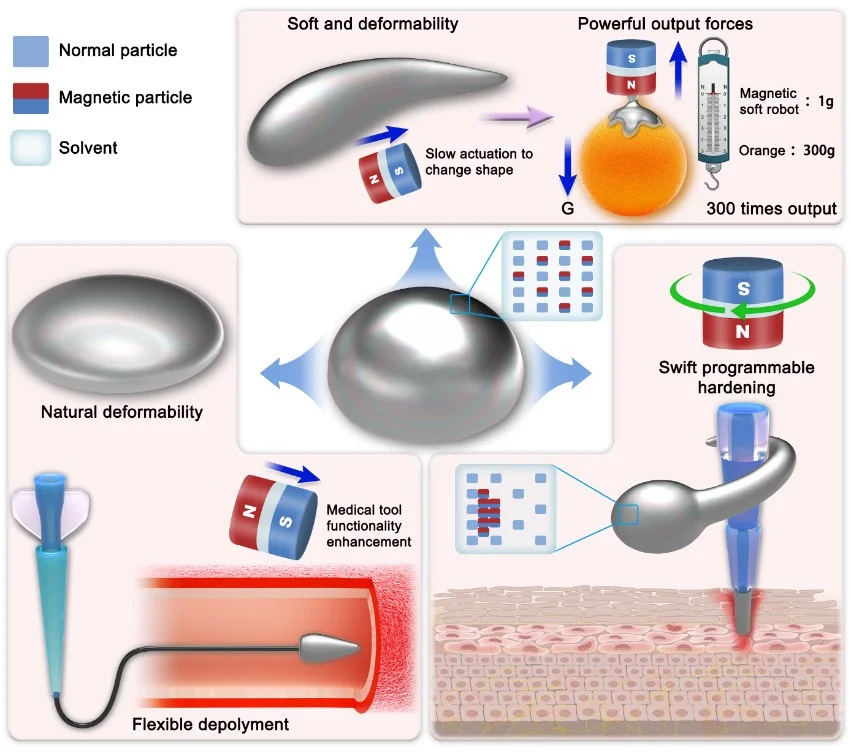

A research team led by Xu Qingsong, professor in the Department of Electromechanical Engineering of the Faculty of Science and Technology at the University of Macau (UM), has developed a novel on-demand hardening magnetic soft robot. With the advantages of on-demand hardening and flexible deployment, the robot not only can perform a given task alone with high output forces, but can also be used in conjunction with existing surgical robots, representing a significant advance in the design and application of magnetically controlled robots. The research results have been published in Research, an internationally renowned journal under Science.

Magnetically controlled robots have shown great advantages in medical applications because of their wireless actuation and control characteristics. However, in actual clinical applications, existing magnetically controlled soft robots have limitations, such as limited functions, small output force, and low structural stiffness. Therefore, there is an urgent need for more flexible and adaptive deployment strategies and design methods to fully utilise the performance of magnetically controlled robots and improve their functions. The magnetically controlled soft robot developed by Prof Xu’s research team is capable of switching its stiffness quickly and in a controlled manner, adhering flexibly to the surface of various objects, and providing powerful output forces. The research results offer a promising way to enable magnetically controlled robots to perform more powerful control functions.

The research team’s experimental results show that using a mixture of magnetic particles and non-Newtonian fluidic soft materials to produce magnetic soft robots can achieve programmable hardening, controlled adhesion, soft reconfiguration, and other properties. By applying an external magnetic field, a 1-gram magnetic soft robot can leverage its adhesion and magnetic actuation to pick up an object 300 times its weight. The soft robot can adhere to a variety of object surfaces, enabling the ability of magnetic actuation with improved performance. The soft robot can be used in conjunction with traditional surgical robots to provide precise magnetic navigation and control, as well as a broader range of functions, including adhesion grasping and related operations. In addition, the non-Newtonian properties of the soft robot can be activated by applying a rapidly changing wireless magnetic field. This enables the robot to change between fluid and solid forms in real time and a controlled manner, facilitating swift liquid-solid phase transitions.

The magnetic soft robot developed by Prof Xu’s research team has the following advantages: 1) It has an ultra-soft structure and good adhesion properties that allow flexible deployment, and it can be used in collaboration with existing surgical equipment; 2) Its adhesion properties can be controlled and adjusted by an external magnetic field, which helps perform more functions; 3) It can achieve swift programmable hardening and improve its mechanical strength and stiffness, and provide significant output forces. According to the research team, the realisation of a powerful magnetically controlled robot is of great value for advanced medical applications, and the proposed design ideas and utilisation strategies have reference significance for research in the field.

Prof Xu Qingsong is the corresponding author of the study, and Xu Zichen, a PhD student in the Department of Electromechanical Engineering of UM’s Faculty of Science and Technology, is the first author. PhD student Chen Yuanhe also contributed to the study. The research project was supported by the National Natural Science Foundation of China (File no: 52175556), the Science and Technology Development Fund of the Macao SAR (File no: 0102/2022/A2, 0004/2022/AKP, and 0153/2019/A3), and UM (File no: MYRG2022-00068-FST and MYRG-CRG2022-00004-FST-ICI). The full version of the research article can be viewed at: https://spj.science.org/doi/abs/10.34133/research.0262.

澳門大學科技學院機電工程系教授徐青松的研究團隊開發出一種新型磁控可塗抹的按需硬化軟體機器人,具有快速可控硬化和靈活部署的優勢,不僅可以憑藉強大輸出力單獨完成指定任務,還可與現有的手術機器人協同使用,在磁控機器人的設計與應用方面取得重大進展。研究成果已於Science旗下國際知名期刊《研究》發表。

磁控機器人因其無線驅動和控制的特性,在醫療應用中體現出巨大優勢。但在實際臨床應用中,現有的磁控機器人存在功能少、輸出力小、結構剛度小等局限性。因此,磁控機器人急需更加靈活、更強自適應性的部署策略和設計方法,才能充分發揮出其效能。徐青松研究團隊開發的磁控機器人具有自身硬度快速可控切換的能力,可以靈活地黏附在各種物體表面,並提供強大的磁控輸出力。該研究結果進一步實現磁控機器人取得更強大的操控功能。

研究團隊的實驗結果表明,採用磁性顆粒和非牛頓流體軟材料的混合物來製作磁控機器人可以實現可編程硬化、可控黏附、柔軟可重構等特性。通過施加外部磁場,借助磁控機器人的黏附和磁驅動,重量1克的磁控機器人能夠抓起自身300倍重量的物體。該磁控機器人可以黏附在各種物體的表面,賦予其磁性驅動的能力,從而提升操控性能。磁控機器人能夠與傳統手術機器人一起協同使用,為其提供精準的磁驅動導航和控制,以及提供更多樣化的功能,包括黏附抓取等相關操作。此外,磁控機器人還可通過施加快速變化的無線磁場來激活當中的非牛頓特性,使其可以在流體和固體形態之間進行實時可控的切換,從而快速實現硬度切換。

徐青松研究團隊開發的磁控機器人具有以下優點:1. 具有超柔軟的結構和良好的黏附特性,可以實現靈活的部署,並可與現有的手術設備協同使用;2. 其黏附特性可以由外加磁場可控調整,有助於實現更加多樣化的功能;3. 能夠實現快速的可編程硬化,提高自身機械剛度與硬度,並且提供強大輸出力。團隊表示,設計出功能強大的磁控機器人在先進醫療應用方面具有重要價值,所提出的設計思想與應用策略對於相關研究具有重要的借鑒意義。

該研究的通訊作者為徐青松,第一作者為澳大科技學院機電工程系博士生徐子晨,博士生陳遠赫也對研究作出重要貢獻。研究項目獲國家自然科學基金(檔案編號:52175556)、澳門特別行政區科學技術發展基金(檔案編號:0102/2022/A2, 0004/2022/AKP和0153/2019/A3)及澳門大學(檔案編號:MYRG2022-00068-FST和MYRG-CRG2022-00004-FST-ICI)資助。全文可瀏覽:https://spj.science.org/doi/abs/10.34133/research.0262