A research team led by Hui Kwun Nam, associate professor in the Institute of Applied Physics and Materials Engineering (IAPME), University of Macau (UM), has recently made important progress in the research of anode materials for potassium-ion batteries, which is expected to provide solutions for poor cycling stability problems for the development of the next generation of energy storage systems. The team has also further optimised the materials to achieve higher energy density while improving the stability and safety of the batteries. The two research results have been published in the international journal Advanced Energy Materials and Advanced Functional Materials and patents have been applied for them in China.

At present, the use of traditional fossil fuels has led to the deterioration of the global environment and the depletion of non-renewable resources, which is a major problem facing mankind. It is imperative to vigorously develop new renewable energy sources, such as solar energy, wind energy, geothermal energy, and tidal energy. However, most renewable energy sources have intermittent and regional characteristics. The construction of a smart grid is an indispensable component for the large-scale and rational use of the above renewable resources. For the construction of a smart grid, a stable, efficient, and inexpensive energy storage system is essential. It seems to be a good choice to use the currently widely used lithium-ion battery as an energy storage system. However, the uneven distribution and low overall abundance of lithium resources restrict its large-scale application. In contrast, potassium is highly abundant with a more balanced distribution and its electrode potential is similar to that of lithium. For this reason, in the past five years, the research of potassium-ion batteries has received much attention.

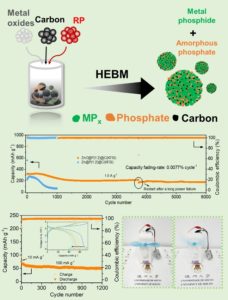

Anode materials are critical to the performance of batteries. Among the many anode materials of potassium-ion batteries, phosphorus and its metal phosphides are favourable competitors for the anode electrodes of the batteries because of their high specific capacity and reasonable discharge voltage. However, these kinds of electrode materials are based on conversion or even alloying reaction mechanisms. They will undergo huge volume changes after cycling and will result in extremely poor cycling stability, which makes it difficult to meet the actual application requirements. In order to solve the abovementioned problems, some solutions, including complicated morphology control and expensive flexible substrates, have been reported, and significant improvements have also been made, but complex and high-cost solutions remain difficult to put into practice. By analysing previous studies, the research team found that the oxidation of phosphorus and its metal phosphides seems to be unavoidable in the synthesis of materials or in the preparation of electrodes. However, phosphide electrodes have a high electrochemical stability and phosphates are susceptible to amorphisation. For this reason, in situ-formed amorphous phosphate impurities can act as buffers to reduce the volume expansion of phosphide electrodes. To this end, the team took a different approach by using metal oxide as the raw material and synthesising amorphous phosphate-doped metal in one step through a simple ball milling method. This in situ-formed amorphous phosphate has a uniform distribution and can be used as a buffer to effectively reduce the volume expansion of the metal phosphide electrode. As a general synthesis strategy, the team synthesised a total of ten metal phosphides (VPx, CrPx, MnPx, FeP, FeP2, FeP4, CoP, NiP3, CuP2, and ZnP2) containing amorphous phosphate-doped metal phosphides. Among them, ZnP2 as a representative was tested and analysed.

Based on the above analysis, the research team carried out further investigation. First, the controllable zinc phosphate content was achieved simply by controlling the ratio of Zn, ZnO, and P raw materials and three zinc phosphide composites with different contents of zinc phosphate were prepared. The mass fractions of zinc phosphate are 10, 20, and 30 wt%, respectively. Secondly, non-flammable triethyl phosphate (TEP) was used as the electrolyte to improve the safety of the battery. High capacity (the highest capacity was 571.1 mAh g−1 at a current density of 0.1 A g−1), high stability (94.5% capacity retention after 1000 cycles), and high safety (no burning under open flame conditions) were realised for the zinc phosphide composite electrodes.

In the two studies above, Ji Shunping, a PhD student in the IAPME is the first author. Prof Hui and Assistant Professor Chen Shi in the IAPME, as well as Prof Hui Kwan San at the University of East Anglia and Prof Shao Zongping of Curtin University are the corresponding authors. IAPME Chair Professor Tang Zikang and Associate Professor Li Haifeng as well as PhD students Li Junfeng and Wang Shuo also made important contributions to the supplementation and analysis of experiment data in the studies. The project was funded by the Science and Technology Development Fund of Macao (File no: 0041/2019/A1, 0046/2019/AFJ, 0021/2019/AIR) and UM (File no: MYRG2018-00192-IAPME and MYRG2020-00187-IAPME).

The full version of the articles can be viewed at

https://onlinelibrary.wiley.com/doi/10.1002/aenm.202101413

https://onlinelibrary.wiley.com/doi/10.1002/adfm.202200771?af=R

澳門大學應用物理及材料工程研究院副教授許冠南的研究團隊在鉀離子電池負極材料的研究中取得重要進展:1. 有望為下一代儲能系統循環穩定性差的問題提出解決方案;2. 團隊亦研發出擁有高容量、高穩定性和高安全性三大條件的鉀離子電池。兩項研究成果已發表於國際知名期刊《先進能源材料》(Advanced Energy Materials)與《先進功能材料》(Advanced Functional Materials)並成功申請中國專利。

目前,傳統化石燃料的使用導致全球環境惡化及不可再生資源的枯竭是人類面臨的重大難題。大力發展新的可再生能源,如太陽能、風能、地熱能、潮汐能等是未來趨勢。不過,大多數可再生能源具有間歇性及地域性的特點。智能電網的建設是規模化和合理化使用可再生資源不可或缺的組成。對智能電網的構建而言,穩定高效且價格低廉的儲能系統至關重要。使用目前廣泛應用的鋰離子電池作為儲能系統是一個不錯的抉擇,但鋰資源的分佈不均及總體豐度低制約其大規模應用。相比而言,鉀元素豐度高,分佈較為均衡,並且與鋰具有相近的電極電勢。為此,近5年來,鉀離子電池的研究受到重視。

負極材料對電池的性能影響至關重要,在眾多的鉀離子電池負極材料中,磷及其金屬磷化物具有高的比容量及合理的放電平台,是鉀離子電池負極的有利競爭者。但是,這類基於轉化甚至合金化反應機制的電極材料,在循環過程中會發生巨大的體積變化,從而導致極差的循環穩定性,很難滿足實際應用需求。為解決以上難題,一些複雜的形貌控制及昂貴的柔性負載等方案被報導,也取得了顯著的改善,但複雜且高成本的解決策略很難實際應用。團隊通過分析以往的研究發現,磷及其金屬磷化物在材料合成或者電極片製備過程中,發生氧化的現象似乎難以避免。然而,磷酸根具有穩定的電化學穩定性,同時磷酸鹽也易於非晶化。顯然,非晶態材料在緩衝體積膨脹方面也更具優勢。為此,團隊通過簡單的球磨法一步合成非晶態磷酸鹽摻雜的金屬磷化物。這種原位形成的非晶磷酸鹽分佈均一,作為緩沖劑能有效降低金屬磷化物電極的體積膨脹。作為一種通用的合成策略,團隊共計合成了10種(VPx, CrPx, MnPx, FeP, FeP2, FeP4, CoP, NiP3, CuP2, 和 ZnP2)含有非晶態磷酸鹽摻雜的金屬磷化物。其中,ZnP2作為代表被重點進行了測試分析。研究證實,有非晶磷酸鹽存在的ZnP2表現出更優異的循環穩定性,在1.0 A g−1電流密度條件下,循環6000次後,其可逆比容量仍然高達177 mAh g−1。優異的循環穩定性得益於體積膨脹的緩減,使得表面形成的固態電解質界面(SEI)更加穩定。為了驗證實際應用的可行性,採用普魯士藍類似物作為正極組裝測試了其全電池性能,在長達1200次的循環測試後,其容量仍保持為49 mAh g−1 (0.1 A g−1),容量基於正極和負極材料的總質量進行計算。

基於以上的分析,研究團隊開展了進一步的工作,首先通過簡單地控制Zn,ZnO和P原料的投放比例實現了磷酸鋅含量的可控調節;並且製備了三個不同磷酸鋅比例的磷化鋅複合材料,磷酸鋅的質量分數分別為10, 20 和 30wt%。其次,採用了不燃的三乙基磷酸酯(TEP)作為電解液體系,實現了磷化鋅複合電極的高容量(在 0.1 Ag−1電流密度下最高容量為571.1 mAhg−1),高穩定性(1000次循環後,容量保持率為94.5%)和高安全性(明火條件下也不燃燒)。

以上兩項研究的第一作者為澳大應用物理及材料工程研究院博士生季順平,共同通訊作者包括澳大應用物理及材料工程研究院助理教授陳石和副教授許冠南、東英吉利大學教授許冠山和科廷大學教授邵宗平。澳大應用物理及材料工程研究院講座教授湯子康和副教授李海峰,博士生李俊峰、王碩等對研究的實驗數據補充及分析做出了重要貢獻。該項目由澳門特別行政區科學技術發展基金(檔案編號:0041/2019/A1,0046/2019/AFJ, 0021/2019/AIR)和澳門大學(檔案編號:MYRG2018-00192-IAPME和MYRG2020-00187-IAPME)資助。

研究全文可分別瀏覽:

https://onlinelibrary.wiley.com/doi/10.1002/aenm.202101413

https://onlinelibrary.wiley.com/doi/10.1002/adfm.202200771?af=R

一步球磨法製備嵌入原位形成的

無定形磷酸鹽的金屬磷化物複合材料示意圖

A schematic illustration of the preparation of metal phosphide

composites embedded with in situ-formed

amorphous phosphates by one-step ball milling

(中)許冠南

Hui Kwun Nam (center)