| Wai-Meng QUACH, 郭偉明 (Stephen) Associate Professor (wmquach@um.edu.mo) Google scholar ; ORCiD: 0000-0002-4311-8979 AuthorID: 6505651725 ; ResearcherID: AAS-9969-2020 https://repository.um.edu.mo/profile/wmquach https://www.fst.um.edu.mo/people/wmquach/ https://www.impactio.com/researcher/wmquach Bio | Profile | Research | PhD-PostDoc Opportunities |

Research for Curiosity !

Research Interests

Steel structures; Cold-formed steel; Additive manufacturing for construction; High performance structural materials; Composite structures; Strengthening and Repair Structural repair

Research Themes

The Role of Manufacturing Processes (Cold-forming, Hot-finishing, 3D Printing) on the Mechanical and Structural Performances of Metal Structures

1. Cold-formed metal structures

No longer a Dream for predicting geometric imperfection, residual stresses and strength enhancement in cold-formed steel structures realistically ! A deterministic approach with advanced numerical modeling of manufacturing processes is now a solution.

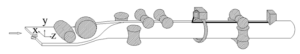

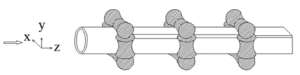

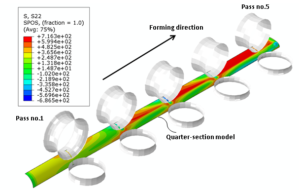

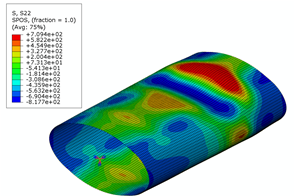

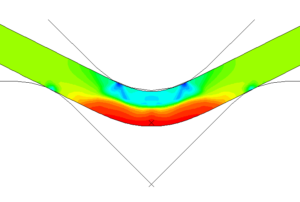

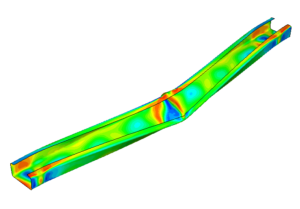

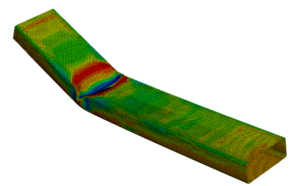

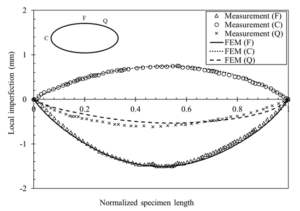

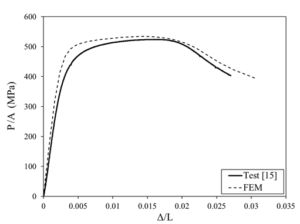

Million tons of cold-formed metal building products are used in construction industry around the world each year. This trend is kept increasing due to their construction efficiency in Modular integrated Construction (MiC). The structural performance of cold-formed thin-walled metal structures is known to be sensitive to initial imperfections which include both geometrical imperfection and cold work due to forming. Traditionally, this cold work effect has been taken into account by using separate specifications of mechanical properties for the flat portions and the corner regions in conjunction with idealized residual stresses models which are based on inappropriate assumptions disregarding the effect of the manufacturing process. Indeed, various cold-formed sections are fabricated by different manufacturing processes (Figs. 1 & 2). Hence, a research has been being carried out to seek for the solution to overcome this shortcoming.

Dr. Quach’s research has been focused on the development of various scientific tools (i.e. analytical models, empirical models, and hybrid analytical-finite element approaches) to accurately model manufacturing processes and quantify initial imperfections and the cold work effect (i.e., residual stresses and plastic strains) and in various types of cold-formed members (e.g. channels and hollow sections). The main contribution from this research is to correct the major deficiencies in existing knowledge and existing design approaches by using these proposed tools. The findings confirm the effect of the manufacturing process on the mechanical and structural performance of cold-formed metal members. The proposed methods/tools can be used to predict geometric imperfections, residual stresses and strength enhancement in cold-formed metal structures realistically.

An integration of these proposed scientific tools forms a novel and unified approach for the analysis and design of cold-formed thin-walled structures. This new approach can be used for optimizing the forming parameters of cold-formed steel sections and will greatly reduce the need for laboratory testing in the development of design rules. This research is being developed at three main directions:

(a) Stress-strain models of thin sheet metals;

(b) Simulations and predictions for enhanced strengths of cold-worked materials;

(c) Simulations and predictions for initial imperfections (including geometrical imperfections, residual stresses, plastic strains) in cold-formed members and their effect on structural performance (Figs. 3~9).

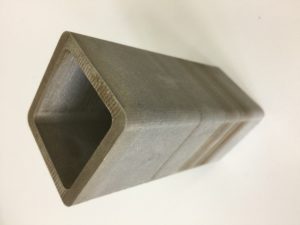

2. Metal 3D printing in Construction

Additive manufacturing, commonly known as 3D printing, is an evolutional technology which has already been embraced by different industries, such as manufacturing, aerospace and biomedical engineering. Despite the exciting prospect of its application in civil engineering, additive manufacturing technology is still at a perceived stage for construction industry. The benefits and potential in construction industry are rarely known in the field at this stage. This multi-disciplinary research is under collaboration between University of Macau (UM) and Southern University of Science and Technology (SUSTech). It aims to investigate the mechanical properties and structural performance of additively manufactured metal tubular sections (see Figs. 10 and 11). So far, high strength steel tubular stub columns additively manufactured by selective laser melting (SLM) with different scanning patterns, have been tested. The anisotropy on mechanical properties has been examined through tensile coupon tests in both longitudinal and transverse directions. The influences of scanning patterns on mechanical properties and structural behavior of as-printed high strength steel tubular sections stub columns were also investigated. The test results have been used to assess the applicability of existing design provisions that originally developed for conventionally produced hot-rolled and cold-formed steel tubular sections to the additively manufactured high strength steel tubular sections.

Structural Repair under Marine Environments

Collaborators

- Dr. Miguel ABAMBRES (IST, Lisbon)

- Dr. Yan-Cheng CAI (Former PostDoc of UM; now Assistant Professor at HKPolyU)

- Dr. Man-Tai CHEN (Former PostDoc of UM; now Assistant Professor at Shanghai Jiao Tong University)

- Professor Jian-Fei CHEN (SUSTech)

- Professor Kwok-Fai CHUNG (HKPolyU)

- Professor Ran FENG (HIT)

- Professor Hieng-Ho LAU (Swinburne University of Technology, Malaysia)

- Professor Jin-Guang TENG (HKPolyU)

- Dr. Chui-Huon Tina TING (Curtin University, Malaysia)

- Professor Ming YAN (SUSTech)

- Dr. Ye YAO (PhD graduate; now Lecturer at Northeastern University, China)

- Professor Ben YOUNG (HKPolyU)

- Professor Jun-Jie ZENG (Guangdong University of Technology)

Projects and Grants

- Quach, W.M. (PI), Yan, M. (Co-PI), Feng, R. (Co-PI), 3D Printing of High-Performance Metal Structural Members for Intelligent Construction (3D打印高性能金屬結構構件在智能建造中的應用研究), FDCT-MOST project proposal, submitted to the Fundo para o Desenvolvimento das Ciências e da Tecnologia (FDCT) of the Macao S.A.R., 2021 – 2023 (36 months). [MOP 2.5M; Under Review]

- Quach, W.M. (PI), “Macau Youth Scholar Program 澳門青年學者計劃” funded by “The Association for Promotion of Science and Technology of Macau 澳門科學技術協進會 (MAPST)” and “The Office of China National Postdoctoral Council 國家人力資源和社會保障部全國博士後管委會辦公室 (CNPC)” [mutually funded by UM Macao Talent Program (UMMTP)], 04/01/2021 – 03/01/2023. [RMB 300K; AM2020002]

- Quach, W.M. (PI), “Macau Youth Scholar Program 澳門青年學者計劃” supported by UM Macao Talent Program (UMMTP) [mutually funded by MAPST (澳門科學技術協進會 ) and CNPC (國家人力資源和社會保障部全國博士後管委會辦公室)], 04/01/2021 – 03/01/2023. [MOP 360K; UMMTP2020-MYSP-003]

- Quach, W.M. (PI), Structural Repair of Reinforced Concrete Members with FRP and UHPC under Marine Environments (FRP、UHPC加固水下梁柱) – A sub-project, under Key Special Project for Introduced Talents Team of Southern Marine Science and Engineering Guangdong Laboratory (Guangzhou), 01/09/2019 – 30/08/2022. [RMB 500K]

- Chen J.F. (PI), Teng J.G. (PI), …, Quach W.M. (Co-PI), et al., 南方海洋科学与工程广东省实验室(广州), 重大专项五-项目3“海洋工程新材料及新型结构”, 01/09/2019 – 30/08/2022. [RMB 26M]

- Lau, H.H. (PI), Muhammad, E.R. (Co-I), Ting, C.H.(Co-I), Quach, W.M.(Co-I), A mathematical model for high strength cold-formed steel screwed connection under cyclic loading, funded by the Fundamental Research Grant Scheme (FRGS) of the Ministry of Education, Malaysia, 01/01/2019 – 31/03/2022. [MYR 109K]

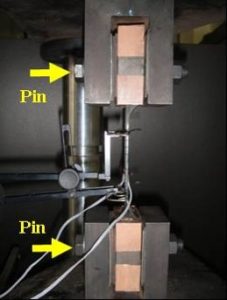

- Quach, W.M. (PI), Structural performance of self-drilling screwed connections under cyclic loading for cold-formed high strength steel structures, funded by the Research Committee of University of Macau, 01/01/2019 – 31/12/2021. [MOP 513.8K; MYRG2018-00099-FST]

- Quach, W.M. (PI) and Lau, H.H. (Co-I), Structural performance and design of self-drilling screwed connections in high strength steel thin-walled structures, funded by the Fundo para o Desenvolvimento das Ciências e da Tecnologia (FDCT) of the Macao S.A.R., 31/03/2016 – 30/03/2019. [MOP 725K; FDCT/073/2015/A2]

- Quach, W.M. (PI), Design of cold-formed and hot-finished columns with elliptical hollow sections, funded by the Fundo para o Desenvolvimento das Ciências e da Tecnologia (FDCT) of the Macao S.A.R., 18/06/2015 – 17/06/2018. [MOP 1.25M; FDCT/129/2014/A3]

- Quach, W.M. (PI), One-time special Fund for PhD Student Support, funded by the University of Macau, 01/01/2015 –31/12/2017. [MOP 360K]

- Quach, W.M. (PI), The Cold-Work Effect on the Column Behaviour of Cold-Formed Steel Oval Hollow Sections, funded by the Research Committee of University of Macau, 01/05/2013 – 31/04/2016. [MOP 566.5K; MYRG073(Y1-L2)-FST13-QWM]

- Quach, W.M. (PI), Residual Stresses in Cold-Formed Stainless Steel Rectangular Hollow Sections due to Cold Bending, funded by the Research Committee of University of Macau, 01/09/2010 – 28/02/2013. [MOP 630.5K; RG061/09-10S/QWM/FST]

- Quach, W.M. (PI), Compression Strength of Cold-Formed Steel Channel Sections with the Strength Enhancement in Corners, funded by the Fundo para o Desenvolvimento das Ciências e da Tecnologia (FDCT) of the Macao S.A.R., 01/09/2007 – 01/09/2010. [MOP 759.5K; FDCT/011/2007/A1]

- Quach, W.M. (PI), Compression Strength of Cold-Formed Steel Channel Sections with the Strength Enhancement in Corners, funded by Research Committee of University of Macau, 01/09/2007 – 01/09/2010. [MOP 292.4K; RG051/06-07S/QWM/FST]

- Quach, W.M. (PI), Initial Material Imperfection in Cold-Formed Circular Hollow Sections, funded by the Research Committee of University of Macau, 01/06/2006 – 31/12/2008. [MOP 350K; RG070/05-06S/QWM/FST]

Selected Publications

Journal Papers (*Corresponding author; ^ UM student or UM Post-Doc.)

- Liao, J.J., Zeng*^, J.J., Gong, Q.M., Quach*, W.M., Gao, W.Y., and Zhang, L.H. (2022), Design-oriented stress-strain model for FRP-confined ultra-high performance concrete (UHPC), Construction and Building Materials, 318, 126200. [Q1 in Civil Eng.]

- Zeng*^, J.J., Ye, Y.Y., Quach, W.M., Lin, G., Zhuge, Y., and Zhou, J.K. (2022), Compressive and transverse shear behaviour of novel FRP-UHPC hybrid bars, Composite Structures, 281, 115001. [Q1 in Materials Science, Composites]

- Liao, J.J., Yang, K.Y., Zeng*^, J.J., Quach*, W.M., Ye, Y.Y., and Zhang, L.H. (2021), Compressive behavior of FRP-confined ultra-high performance concrete (UHPC) in circular columns, Engineering Structures, 249, 113246. [Q1 in Civil Eng.]

- Ye, Y.Y., Smith, S.T., Zeng*^, J.J., Zhuge, Y., and Quach, W.M. (2021), Novel ultra-high-performance concrete composite plates reinforced with FRP grid: Development and mechanical behaviour, Composite Structures, 269, 114033. [Q1 in Materials Science, Composites]

- Fernando, D., Teng*, J.G., Quach, W.M., and De Waal, L. (2020), Full-range stress-strain model for stainless steel alloys, Journal of Constructional Steel Research, 173, 106266. [Q1 in Civil Eng.; Q1 in Construction & Building Technology]

- Yao^, Y., Quach*, W.M., and Young, B. (2020), Simplified models for residual stresses and equivalent plastic strains in cold-formed steel elliptical hollow sections, Thin-Walled Structures, 154, 106835. [Q1 in Civil Eng.]

- Yan^, J.J., Song, H., Dong, Y.P., Quach*, W.M. , and Yan*, M. (2020), High strength (~2000 MPa) or highly ductile (~11%) additively manufactured H13 by tempering at different conditions, Materials Science and Engineering A, 773, 138845. [Q1 in Materials Science – Multidisciplinary; Q1 in Metallurgy & Metallurgical Eng.]

- Yao^, Y., Quach*, W.M., and Young, B. (2019), Cross-section behavior of cold-formed steel elliptical hollow sections – a numerical study, Engineering Structures, 201, 109797. [Q1 in Civil Eng.]

- Cai, Y., Quach*, W.M., and Young, B. (2019), Experimental and numerical investigation of concrete-filled hot-finished and cold-formed steel elliptical tubular stub columns, Thin-Walled Structures, 145, 106437. [Q1 in Civil Eng.]

- Yao^, Y., Quach*, W.M., and Young, B. (2019), Finite element-based method for residual stresses in cold-formed steel hollow sections, Engineering Structures, 188, 24-42. [Q1 in Civil Eng.]

- Yan^, J.J., Chen*^, M.T., Quach, W.M., Yan, M., and Young, B. (2019), Mechanical properties and cross-sectional behavior of additive manufactured high strength steel tubular sections, Thin-Walled Structures, 144, 106158. [Q1 in Civil Eng.]

- Cai, Y., Quach*, W.M., Chen, M.T., and Young, B. (2019), Behavior and design of cold-formed and hot-finished steel elliptical tubular stub columns, Journal of Constructional Steel Research, 156, 252-265. [Q1 in Civil Eng.; Q1 in Construction & Building Technology]

- Yan^, J.J., Zhou, Y.H., Gu, R.N., Zhang, X.M., Quach*, W.M. , and Yan*, M. (2019), A comprehensive study of steel powders (316L, H13, P20 and 18Ni300) for their selective laser melting additive manufacturing, Metals, 9(86), 1-20. [Q1 in Metallurgy & Metallurgical Eng.]

- Abambres*, M., and Quach, W.M. (2016), Residual Stresses in Steel Members: A Review of Available Analytical Expressions, International Journal of Structural Integrity, 7(1), 70-94. [Q3 in Civil & Structural Eng.; Q3 in Mechanical Eng., according to SJR]

- Quach, W.M., and Young*, B. (2015), Material properties of cold-formed and hot-finished elliptical hollow sections, Advances in Structural Engineering, 18(7), 1101-1114. [Q2 in Civil & Structural Eng.; Q2 in Building & Construction, according to SJR]

- Quach*, W.M., and Huang^, J.F. (2014), Two-stage stress-strain models for light-gauge steels, Advances in Structural Engineering, 17(7), 937-949. [Q2 in Civil & Structural Eng.; Q2 in Building & Construction, according to SJR]

- Quach*, W.M., and Qiu^, P. (2014), Strength and ductility of corner materials in cold-formed stainless steel sections, Thin-Walled Structures, 83, 28-42. [Q1 in Civil Eng.]

- Quach, W.M., Teng*, J.G., and Chung, K.F. (2010), Effect of the manufacturing process on the behaviour of press-braked thin-walled steel columns, Engineering Structures, 32, 3501-3515. [Q1 in Civil Eng.]

- Quach, W.M., Teng*, J.G., and Chung, K.F. (2009), Residual stresses in press-braked stainless steel sections – I: Coiling and uncoiling of sheets, Journal of Constructional Steel Research, 65, 1803-1815. [Q1 in Civil Eng.; Q1 in Construction & Building Technology]

- Quach, W.M., Teng*, J.G., and Chung, K.F. (2009), Residual stresses in press-braked stainless steel sections – II: Press braking operations, Journal of Constructional Steel Research, 65, 1816-1826. [Q1 in Civil Eng.; Q1 in Construction & Building Technology]

- Quach*, W.M., and Qiu^, P. (2009), Accurate prediction of mechanical properties for cold-formed stainless steel section, Journal of Yantai University, Natural Science and Engineering Edition, 22(3), 217-228.

- Quach, W.M., Teng*, J.G., and Chung, K.F. (2008), Three-stage full-range stress-strain model for stainless steels, Journal of Structural Engineering, ASCE, 134(9), 1518-1527. [Q1 in Civil & Structural Eng.; Q1 in Building & Construction, according to SJR]

- Quach*, W.M., Teng, J.G., and Chung, K.F. (2007), Finite element predictions of residual stresses in cold-formed steel sections, Progress in Steel Building Structures, 9(3), 26-32.

- Quach, W.M., Teng*, J.G., and Chung, K.F. (2006), Finite element predictions of residual stresses in press-braked thin walled steel sections, Engineering Structures, 28, 1609-1619. [Q1 in Civil Eng.]

- Quach, W.M., Teng*, J.G., and Chung, K.F. (2004), Residual stresses in steel sheets due to coiling and uncoiling: a closed form analytical solution, Engineering Structures, 26, 1249-1259. [Q1 in Civil Eng.]