| Location | E11-G031 |

| Academic Staff in charge | Prof. Chi Tat KWOK; Prof. Kin Ho LO |

| Technician | Po Kee WONG |

| Telephone | (853) 8822-8057, 4292 |

Objective

Lasers have been applied extensively in industry. They are usually used for cutting, welding, drilling, surface modification, etc. The purposes of this laboratory are

- To allow the students to have some ideas of laser technology in manufacturing processes.

- To provide facilities for students’ final projects and MSc and PhD students’ theses.

- To serve local industries.

Facilities

1. Corrosion testers

Laser System

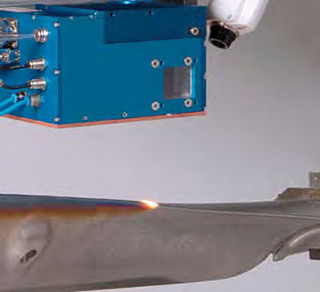

The laser system consists of the fiber-couple diode laser module (Laserline LDM 1000-1000) and the CNC XYZ table. Diode laser with near infra wavelength provides high energy absorptivity to metals.

Specifications

| Classification | Class IV |

| Central wavelength | 900 – 990 nm |

| Maximum power | 2300 W |

| Beam quality | 110 mm rad |

| Optical fiber | 1000 μm |

|

|

|

Steps for laser processing:

- Design scanning sequences with the aid of drawing software, such as AutoCAD and Corel Draw.

- The drawing is converted to a CNC program that can be recognized by the controller of the CNC machine.

- Adjust the desired power level and scanning speed of the laser machine.

The laser beam is transmitted through an optical fiber. The high energy beam acts as a heat source and is controlled by the CNC machine for processing.

Applications of laser:

Experiments

- Laser transformation hardening

- Laser surface alloying

- Laser welding

- Laser cutting

Courses supported

| EMEB121 | Engineering Materials |

| EMEB351 | Advanced Materials for Engineers |

| EMEB355 | Corrosion, Wear and Degradation of Materials |

| EMEB410 | Design Projects |

| ELME702 | Physics of Materials |

| ELME717 | Special Topics in Manufacturing I: Laser Materials Processing |

| ELME718 | Special Topics in Manufacturing II : Surface Engineering |