| Location | E11-G032 |

| Academic Staff in charge | Prof. Kun Pang KOU; Prof. Chi Chiu LAM |

| Technician | Ka Man TOU; Ka In HOI |

| Telephone | (853) 8822-4279, 4122, 4287 |

Objective

The main objective of the structures laboratory is to demonstrate and investigate experimentally the behavior of structural elements. To properly illustrate the structural behavior, tests of structural members to destruction are conducted. Tests have been carried out for the determination of the plastic bending capacity of steel beams and the ultimate strength of steel tensile member and steel beam column connections in supporting courses. The laboratory is also equipped with facilities to conduct experimental research in the area of the structural engineering.

Facilities

Size and capacity of work area

There are two work areas in the structures laboratory: (1) the Main Testing Area and (2) the Secondary Testing Area. The area of the main testing area is about 197 m2 (2140 ft2). It is a 2 cells RC box structure with 1000mm thick strong floor and tie down points on 600 mm x 600 mm grid. The design point load of each tie down points is 500 kN. A reaction strong wall of area about 48 m2 (2700 ft2) is located in the main testing area. It is a RC box structure with thickness of 1860mm and tie down points on 600 mm x 600 mm grid. The design point load of each tie down points is 250 kN. A three-dimensional 12.5-tone crane is installed in the main testing area. The area of the secondary testing area is about 155 m2 (1700 ft2) and several test machines such as the UTM and concrete compression test machines were located in this area.

Loading Frame

In the main testing area, there are self-equilibrium loading frames for structural members testing. Those loading frames are suitable for typical steel beam or RC beam tests. Holes are drilled in the columns of the frame to allow flexibility in the test setup. The frame can be modified to suit the testing of structural elements. With proper arrangement of the frame, the capacity of the frame can be achieved up to 1000 kN. Measurement of load, deflection and strain can be done by using a data acquisition system – Measurement Group System 5000. The system is connected through a personal computer that store and display the test data during testing.

|

|

Instrumentation and Heavy Equipment

| Universal Testing Machines (2000 kN) | Universal Testing Machines (250 kN) | MTS Universal Testing Machines (100 kN) |

|

|

|

|

Universal Testing Machines (UTM) applies for high-capacity tension, compression, bend/flex, and shear testing. Featuring a dual test space and long test stroke (300mm and 150mm), these frames are available in 2000kN (for bigger one) and 250kN (for smaller one) capacities. Testing Applications

|

||

Compression Machine (5000 kN)

Testing Applications

- Concrete—Cubes, Cylinders, Beams, Blocks and Bricks

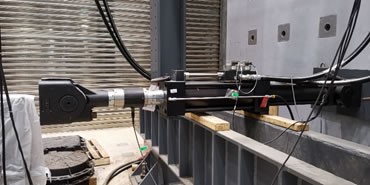

Hydraulic Actuator System

Actuator with 100kN capacity and 254mm stroke

Actuator with 250kN capacity and 500 mm stroke

The actuator system is a component of the testing setup that is responsible for controlling the loading and displacement on the specimen testing.

Testing Applications

- Metals—Bar, Plate, Pipe & Tube, Rebar, Structural

- Wire—Rod, Strand

- Concrete / brick—Beam, wall

Some of the structural element tests were shown in the following figures.

| Steel bolted connection test | Steel beam connection test |

|

|

Courses supported

| CIVL2001 | Mechanics of Materials |

| CIVL2005 | Construction Materials |

| CIVL2006 | Structural Analysis |

| CIVL3000 | Steel Design |

| CIVL3004 | Reinforced Concrete Design |

| CIVL4000/4001 | Graduation Project I / II |